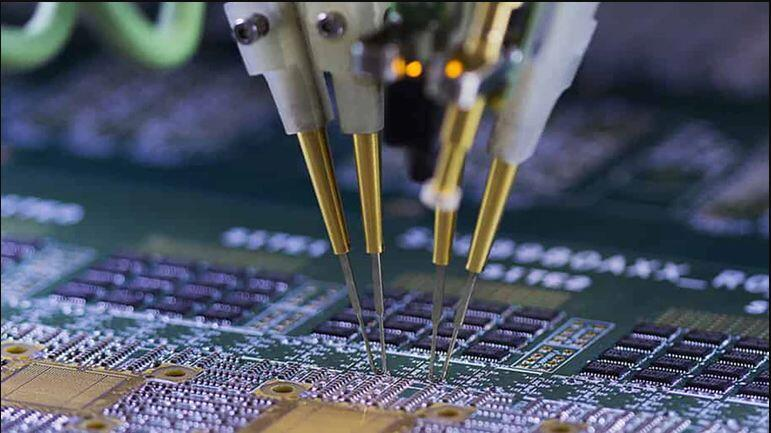

Introduction: With great emphasis placed on modern technology, its innovations are made possible by the use of elementary components such as a smartphone or tablet’s Printed Circuit Board (PCB). Life without technology would be troublesome, as it helps us at the convenience of our fingertips, with additional aid from a computer or even a mobile phone. This does not mean surgically encompassed automatable devices only. Rather, creating complex software applications designed for industrial automation, aerospace systems, medical devices, or even a phone is entirely possible. Each and everything comes under with guidelines of an intricate structure.

The ability to plan and expand complex circuit boards also follows certain prerequisites of precision, reliability, and safety alongside billing. Prism Computer Solutions (PCS) possess the capability of providing assistance in PCB compliance testing, validation, and its optimization while ensuring the industry standards are met sustainably.

Why is PCB Compliance and Testing Done? It is evident. Each and every item created comes with assistance when something malfunctions neatly encapsulated as warranty. Regardless, with not much complexity comes stricter guidelines and legal regulations to follow. For a complex PCB design protocol without any testing, devices failing mid-production is an involuntary act that will make you question your entire decision-making matrix. A regular process that every production set aims to perform is as follows:

Creating compliant marked designs creates PCs of unbeatable, extraordinary performance while devoid of disasters. But be careful! Here comes the “but…” part. Trouble like a product recall due to an electrical malfunction, signal integrity complications resulting in device breakdown, regulatory penalties turning devices into export permits, or worst of all causing a slope increase in cost for manufacturing due to useless components and even fires.

To fix this denouement, your PCB is optimized with required industry standards outlined below Everything melts to IPC with an US and Canadian influence on the electronics industry aka IPC Standards (IPC-2221, IPC A-600, IPC 6012) to guarantee controlled quality fabrics and component functions. They confirm accord with electromagnetic interference (EMI) and Radio Frequency (RF) safety of FCC and CE Certification.

Global UL certification inspires for compliance with electrical safety and fire testing declared irresistible. The pride differentiates and confirms ISO 9001 (asked for quite often by system integrators for quality effectiveness) from basic 13485 compliance having identification in need of documentation.

Comments are closed